Leave Your Message

When embarking on a project that requires durable and reliable door hardware, choosing the right hinges is crucial. Heavy Duty Aluminum Door Hinges stand out as a superior choice for both residential and commercial applications due to their robust construction and impressive weight-bearing capacity. These hinges provide the strength needed to support heavy doors while ensuring smooth operation and longevity, making them a preferred option for various projects ranging from industrial facilities to high-traffic entrances.

Selecting the best Heavy Duty Aluminum Door Hinges involves considering a range of factors, including the specific requirements of your project, the environmental conditions they will face, and the overall aesthetic you wish to achieve. With numerous designs and styles available, it is essential to evaluate aspects such as size, load capacity, and corrosion resistance. By understanding these elements, you can make an informed decision that not only enhances functionality but also aligns with your project's design goals.

In this guide, we will delve into essential tips and considerations for selecting Heavy Duty Aluminum Door Hinges that meet your needs. Whether you're a contractor, architect, or DIY enthusiast, our insights will help you navigate the options available to find the perfect hinges that combine durability, performance, and style.

Heavy duty aluminum door hinges play a crucial role in ensuring the durability and functionality of your doors. These hinges are engineered to support heavier door weights, making them ideal for commercial, industrial, and residential applications. The importance of choosing the right heavy duty aluminum door hinges lies in their ability to withstand frequent use, exposure to harsh environments, and the overall wear and tear that doors endure over time. A quality hinge not only enhances the longevity of the door but also contributes to the safety and security of the space.

When selecting heavy duty aluminum door hinges, consider the following tips to ensure optimal performance. First, assess the weight and size of the door; this will help determine the appropriate hinge size and strength needed for reliable operation. Next, look for hinges that offer corrosion resistance, particularly for applications in humid or outdoor settings. Additionally, pay attention to the installation method; for best results, ensure that the hinges are properly aligned and fastened to support the door’s movement.

In addition to functionality, aesthetics should also be a consideration. Heavy duty aluminum door hinges come in various finishes and styles that can complement your door design. By prioritizing both practicality and appearance, you can select hinges that enhance the overall look and efficiency of your projects.

| Feature | Specification | Importance |

|---|---|---|

| Material | Heavy Duty Aluminum | Corrosion resistant and lightweight |

| Load Capacity | Up to 200 lbs | Ensures durability for heavy doors |

| Hinge Type | Full Mortise | Flush installation, aesthetic appeal |

| Finish | Anodized | Enhanced protection against wear |

| Pin Type | Removable | Ease of installation and maintenance |

| Size | 4" x 4" | Standard size for most heavy doors |

| Warranty | 10 Years | Assurance of quality and reliability |

When selecting heavy-duty aluminum door hinges for your projects, there are several key factors to consider that will ensure you make the right choice for your specific needs. Firstly, the weight capacity of the hinges is crucial; heavy-duty hinges are designed to support larger or heavier doors. Checking the manufacturer's specifications for weight limits will help you ensure that the hinges can handle the load and maintain smooth operation.

Another important aspect to consider is the design and finish of the hinges. Since aluminum hinges come in a variety of finishes, it’s essential to choose one that matches the aesthetic of your door and surroundings. Additionally, you should think about the type of hinge pin—removable or non-removable—as this can affect maintenance and security. Lastly, the environment where the hinges will be used is significant; selecting corrosion-resistant hinges is advisable for areas exposed to moisture or harsh weather conditions, as this will enhance durability and longevity.

When comparing different types of heavy duty aluminum door hinges, it is essential to consider their design and load-bearing capacity. Heavy duty hinges are typically constructed to support larger and heavier doors, making them a vital component in high-traffic areas or commercial settings. Common variations include offset hinges, which allow for more clearance when the door swings open, and continuous hinges that run the full length of the door, distributing weight more evenly. Each design offers unique advantages depending on the specific application and environment.

Additionally, the finish of the aluminum and the type of pins used can affect durability and maintenance needs. For instance, anodized finishes can increase resistance to corrosion and wear, making them suitable for exterior use. Furthermore, adjustable or removable pins can facilitate easier maintenance and replacement without the need to uninstall the entire hinge. Evaluating these factors will help ensure that the selected heavy duty aluminum door hinges meet the requirements of the project while providing longevity and strength in performance.

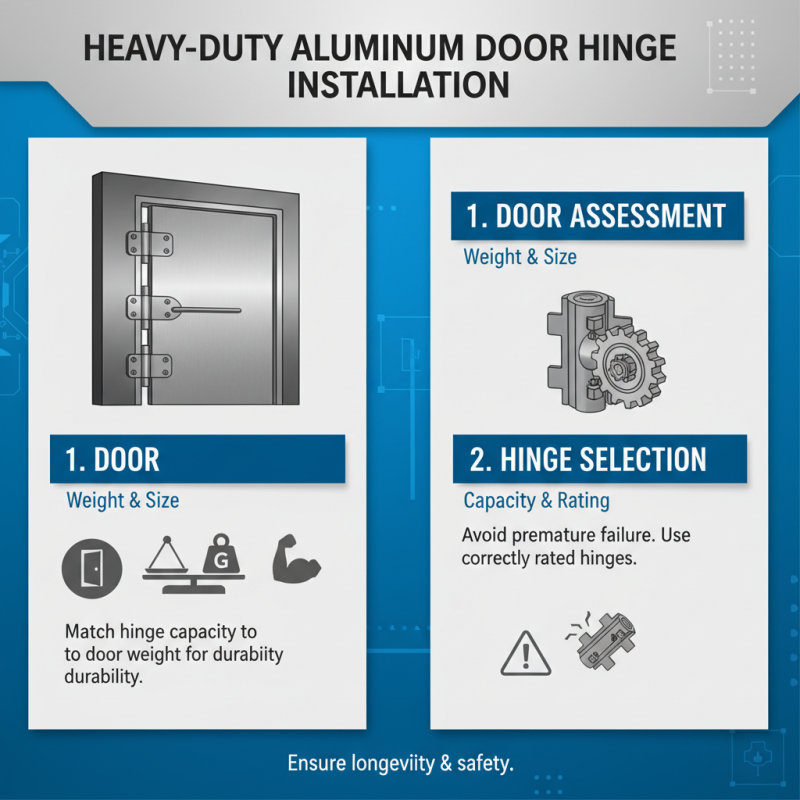

When installing heavy duty aluminum door hinges, several key considerations must be taken into account to ensure durability and performance. Firstly, it's crucial to assess the weight and size of the door that will be fitted. Heavy-duty hinges are specifically designed to support heavier loads, so choosing hinges that can handle the door's weight is essential for longevity. Installing too small or insufficiently rated hinges can lead to premature failure and potential safety hazards.

Secondly, proper alignment is vital during the installation process. Ensuring that the hinges are installed at the correct height and distance from the edge of the door will facilitate smooth operation and reduce strain on the hinge mechanism. Using a level and measuring tools can help achieve accurate placements. Additionally, the use of high-quality fasteners that are compatible with aluminum is necessary to prevent corrosion, which could compromise the hinge's functionality. By paying careful attention to these installation considerations, you can enhance the reliability and lifespan of heavy duty aluminum door hinges in your projects.

Maintaining heavy-duty aluminum door hinges is crucial for enhancing their longevity and ensuring reliable performance in various applications. According to a recent industry report by the American Institute of Steel Construction, properly maintained door hinges can last up to 50% longer than neglected ones.

Regular cleaning is the first step in hinge maintenance. Dirt and debris can accumulate over time, leading to corrosion and wear. Utilizing a soft cloth and a mild detergent solution can effectively remove grime. After cleaning, ensure that the hinges are thoroughly dried to prevent moisture from causing rust.

Lubrication is another essential aspect of hinge maintenance. Industry standards recommend using a silicone-based lubricant, as it repels moisture and provides an effective barrier against rust and corrosion. A study published in the Journal of Construction and Building Materials found that lubricated hinges experienced significantly less friction and wear, prolonging their functional life. Apply lubricant at least twice a year or more frequently in environments prone to humidity or high traffic.

By following these maintenance tips, you can ensure that your heavy-duty aluminum hinges remain durable and functional for many years, reducing the need for premature replacements and contributing to overall project cost-effectiveness.