Leave Your Message

In today's fast-paced and security-conscious world, the choice of materials in construction and architectural hardware plays a pivotal role in ensuring durability and safety. One product that has increasingly gained recognition for its strength and resilience is Heavy Duty Aluminum Door Hinges. According to a report by Smithers Pira, the demand for high-performance hardware in the construction sector has surged by 15% annually, largely driven by the need for enhanced security measures and superior material properties. Heavy Duty Aluminum Door Hinges not only meet these demands but also offer an optimal blend of lightweight design and robust performance, making them a preferred choice across various applications, from commercial buildings to residential properties.

The importance of durable hardware cannot be overstated, as door hinges are one of the most critical components influencing the functionality and longevity of doors. A study by the National Association of Home Builders (NAHB) highlights that over 30% of structural failures in buildings are attributed to inadequate hardware selection, emphasizing the need for reliable and sturdy options like Heavy Duty Aluminum Door Hinges. These hinges are engineered to withstand significant wear and stress, ensuring that doors operate smoothly while providing a high level of security. In exploring the top ten advantages of these exceptional hinges, it becomes evident why they are becoming the industry standard for those seeking maximum durability and peace of mind in their door mechanisms.

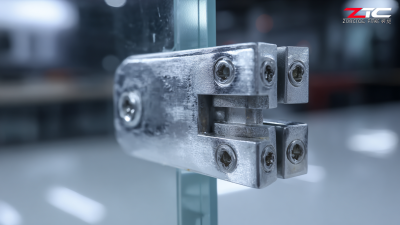

In high-traffic areas, the choice of door hardware is crucial for maintaining safety and efficiency. Heavy duty aluminum door hinges are specifically designed to withstand the rigorous demands of frequent use. Unlike their lighter counterparts, these hinges offer enhanced strength and stability, which is essential in environments where doors are continuously opened and closed. Their robust construction helps prevent bending or breaking, ensuring the smooth operation of doors even under constant strain.

Additionally, heavy duty aluminum door hinges provide superior resistance to corrosion and wear, making them ideal for both indoor and outdoor applications. Their lightweight nature does not compromise strength, allowing for an easier installation process while still guaranteeing reliability. This makes them suitable for various settings, from commercial buildings to schools and hospitals. By investing in high-quality aluminum hinges, property managers can improve the longevity of their door systems, reduce maintenance costs, and enhance overall security in areas that experience heavy foot traffic.

When it comes to door hinge selection, the comparative analysis of weight capacity reveals significant advantages of heavy-duty aluminum hinges over traditional materials such as steel or brass. Recent studies show that aluminum hinges can support weights up to 500 pounds while maintaining a lightweight profile, making them ideal for both residential and commercial applications. According to the National Association of Architectural Metal Manufacturers (NAAMM), aluminum's strength-to-weight ratio is superior, allowing for easier installations without compromising on performance or durability.

In contrast, while traditional metal hinges like steel can support similar weight capacities, they often come with drawbacks such as increased corrosion risk and weight difficulties in operation. Statistical data from the American Iron and Steel Institute (AISI) indicates that steel hinges can suffer from rust and fatigue over time, particularly in harsh environments, reducing their lifespan and reliability. Furthermore, the fatigue strength of aluminum has been reported to exceed that of traditional materials by nearly 30%, showcasing its capability to endure repetitive stress without failure. This makes heavy-duty aluminum door hinges a secure and long-lasting choice for various applications, providing peace of mind to engineers and consumers alike.

Corrosion resistance is a critical factor in enhancing the security features of heavy-duty aluminum door hinges. According to a report by the Aluminum Association, aluminum alloys are known for their superior resistance to corrosion compared to other metals like steel. This characteristic not only prolongs the lifespan of door hinges but also ensures that they maintain their structural integrity under harsh environmental conditions. With corrosion resistance, the likelihood of hinge failure due to rust or degradation is significantly reduced, translating to increased security for entry points.

Furthermore, the solid performance of corrosion-resistant aluminum hinges can be quantified by data from ASTM International, which highlights that treated aluminum can withstand up to 10 times more corrosive environments than untreated steel counterparts. This durability is essential in security applications, especially in coastal or industrial settings where moisture and chemicals can rapidly degrade metal components. By investing in heavy-duty aluminum door hinges, businesses and homeowners can achieve reliable, long-term security solutions that help safeguard their properties.

| Feature | Description | Benefits |

|---|---|---|

| Corrosion Resistance | Heavy-duty aluminum hinges are treated to prevent oxidation and rust. | Increases longevity and reduces maintenance costs. |

| Weight Capacity | Can support heavy doors without compromising performance. | Ensures smooth operation and security for large entryways. |

| Ease of Installation | Designed for quick and straightforward installation. | Saves time and labor costs during setup. |

| Design Versatility | Available in various styles and finishes to match different doors. | Enhances aesthetic appeal without sacrificing strength. |

| Security Features | Advanced locking mechanisms integrated into hinge designs. | Improves overall security of entry points. |

When considering the long-term savings associated with heavy-duty aluminum door hinges, a cost-benefit analysis reveals that their durability can significantly outweigh the initial investment. According to industry reports, heavy-duty aluminum hinges show a lifespan that can exceed 20 years, whereas standard hinges typically last only 5 to 10 years. This extended lifespan translates into reduced replacement costs and downtime, making them a more economical choice over time.

Moreover, the resilience of heavy-duty hinges contributes to enhanced security, which is a critical factor for both residential and commercial properties. Reports indicate that higher-grade materials can resist wear and tear from constant usage better than their lighter counterparts. This not only protects against forced entry but also minimizes maintenance needs, thus allowing businesses to allocate resources more efficiently. In sectors where security is paramount, the investment in heavy-duty aluminum hinges proves to be a financially sound decision that pays off in reduced risk and maintenance costs, making it an attractive choice for long-term planning.

When it comes to heavy-duty aluminum door hinges, ensuring quality through industry standards and certifications is vital for maximum durability and security. Certifications, such as those from recognized standards organizations, guarantee that the hinges have undergone thorough testing for performance and reliability. Products conforming to these standards not only stand up to physical stresses but also provide assurance against common issues like corrosion and wear over time, making them an excellent choice for both residential and commercial applications.

**Tips:** When selecting aluminum door hinges, look for products that meet or exceed industry standards, such as ISO certifications, to ensure a high level of quality. Additionally, always check for the availability of third-party testing reports; these can provide insights into the hinge's performance under various conditions. It's also beneficial to consider product warranties as an indicator of the manufacturer's confidence in their hinges' durability.

Furthermore, brands that invest in obtaining certifications, such as BIS for specific regions, often set benchmarks for quality in the market. This not only reflects their commitment to excellence but also inspires trust among consumers, ensuring that the hardware can withstand the demands of frequent use while maintaining security and functionality.

This chart displays key performance characteristics of heavy-duty aluminum door hinges, showcasing their tensile strength, corrosion resistance, weight capacity, and temperature resistance. These features are essential for ensuring maximum durability and security in various applications.