Leave Your Message

In the world of furniture design, Heavy Duty Drawer Slides play a critical role. According to industry expert John Anderson, "The right drawer slides can transform storage solutions." As consumers demand both functionality and aesthetics, understanding the options is essential.

Heavy Duty Drawer Slides are built to withstand significant weight. They offer smooth operation even under load. Choosing the right slide isn't always straightforward. Not all products on the market meet the same quality standards.

Whether for commercial or residential use, selecting the right type matters. Companies may prioritize cost over quality, leading to disappointing performance. It's crucial to evaluate both brand reputation and product specifications. Overall, informed choices can enhance both utility and longevity in drawer systems.

In 2026, heavy-duty drawer slides are evolving rapidly. The focus is on functionality and efficiency. Innovations are emerging that cater to both industrial and residential needs. Manufacturers are experimenting with materials for enhanced durability. Aluminum and reinforced polymers are popular choices. These materials aim to withstand more weight while ensuring smooth operation.

User-friendliness is a key trend. Soft-close features are becoming standard. This change is not just about luxury; it reflects a desire for practicality and safety. However, many installations still face challenges. A correct fit is crucial for optimal performance. Misalignments can hinder functionality, leading to frustration. Awareness of installation intricacies is essential.

Sustainability is a growing consideration. More producers are exploring eco-friendly practices. Recycling old materials is becoming common. Yet, the transition isn't flawless. Some find it hard to balance cost and environmental impact. Approaching these trends with caution is wise. Recognizing imperfections can lead to better designs in the future. Each innovation carries lessons for the industry.

This chart illustrates the projected growth in the heavy-duty drawer slide market from 2023 to 2026, including trends in material types and their popularity among consumers. The data showcases the increasing preference for stainless steel and the consistent demand for nylon slides due to their durability.

When selecting heavy-duty drawer slides, knowing key specifications and load ratings is essential. A study reveals that heavy-duty slides typically support loads ranging from 200 to 600 pounds. This capacity varies based on materials and design. Indeed, steel slides usually offer greater strength compared to aluminum.

Load ratings are not the only consideration. Durability plays a crucial role in slide performance. High-quality bearings can enhance smoothness and longevity. However, many consumers overlook the impact of installation. Improper installation can lead to unexpected failures, even with high-rated products. Therefore, always review the installation guidelines carefully.

Further, the length of the slide directly affects its load distribution. A shorter slide may buckle under weight if not chosen correctly. Yet, longer slides can sometimes increase drag. Users must balance length and load capacity with careful thought. Real-world conditions may differ from theoretical specifications. User experience can often vary; not all advertised features perform as expected.

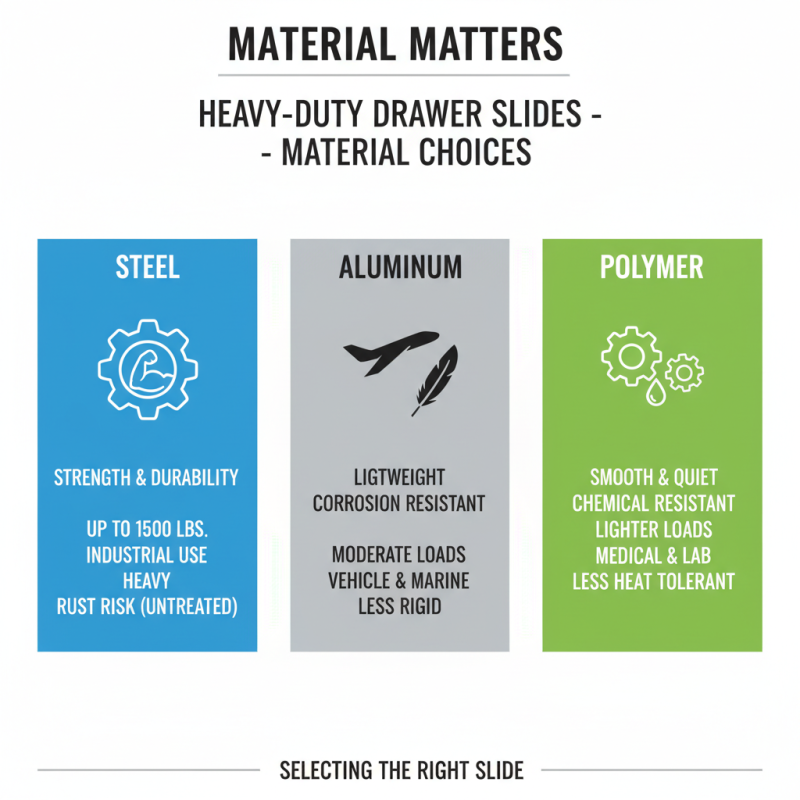

When selecting heavy-duty drawer slides, material choice is vital. Steel, aluminum, and polymer options each have unique properties. Steel slides are strong and durable. They often support heavier loads, making them ideal for industrial applications. Reports indicate that steel can handle loads up to 1,500 pounds. However, they can be heavy and susceptible to rust if not treated properly.

Aluminum slides are lighter and resistant to corrosion, perfect for environments with moisture. They typically handle loads of around 200 to 600 pounds. This makes them suitable for residential use or in lighter industrial settings. Yet, they may not offer the same strength as steel. Cost can also be higher compared to steel options, impacting budget decisions.

Polymer slides, made from plastic materials, have a different appeal. They are lightweight and often quieter. Their load capacity is lower, generally between 100 to 300 pounds. This can be a limitation in heavy-duty applications. Interestingly, their flexibility can sometimes mean wear and tear occurs faster than with metal counterparts. Many users report frustrations with durability over time. Choosing the right material requires careful consideration of what each offers and their shortcomings in various settings.

Installing heavy-duty drawer slides requires careful attention to detail. Begin by gathering your tools: a drill, screwdriver, and measuring tape. Accurate measurements are crucial. Miscalculations can lead to misalignment, causing drawers to stick or not close properly. Take your time when marking where the slides will go. A small error at this stage can create bigger issues later on.

When attaching the slides, make sure they are level. Otherwise, the drawer will not function smoothly. Tighten screws securely but avoid over-tightening; this could damage the slide. Use a clamp if needed to hold the slides in place. After installation, test the drawer's movement. It should glide effortlessly. If it doesn’t, reevaluate your measurements and alignments.

Inspecting your work might reveal spots that need improvement. Don’t hesitate to make adjustments after installation. Not every draw will work perfectly on the first try. Sometimes, it takes a few attempts to achieve optimal performance. Regular maintenance is essential too. Dust buildup can hinder operation. A little upkeep goes a long way in preserving functionality.

| Dimension | Material | Weight Capacity (lbs) | Extension Type | Installation Method | Price Range (USD) |

|---|---|---|---|---|---|

| 16 inches | Steel | 500 | Full Extension | Side Mount | $30 - $50 |

| 18 inches | Aluminum | 600 | Partial Extension | Bottom Mount | $25 - $45 |

| 24 inches | Stainless Steel | 700 | Full Extension | Side Mount | $40 - $70 |

| 30 inches | Galvanized Steel | 800 | Full Extension | Bottom Mount | $50 - $90 |

Maintaining heavy-duty drawer slides is crucial for their longevity and performance.

Regular inspections help identify wear and tear before it becomes a problem. The average lifespan of a heavy-duty slide

is around 20,000 cycles, but neglect can reduce this significantly. Keeping

them clean is essential. Dust and debris can hinder smooth operation, leading to damage.

Lubrication is another key factor. A study from industry experts indicates that well-lubricated slides can last up

to 30% longer than those that are not. Use a suitable lubricant to avoid

buildup. A light application helps in reducing friction, but too much can attract more dust. Pay attention to the

type of lubricant used; some may not be compatible with specific materials.

Checking the installation is also important. Improper alignment can add

stress to the mechanism. This may cause uneven wear. Adjusting slides occasionally can greatly improve their functionality.

Regular maintenance needs to be part of your routine. By investing time in care, you ultimately save money on

replacements and ensure smooth operation.